Home > Products > Electro permanent magnetic Chucks for Workholding > Magnetic Chucks for Lathes

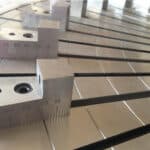

Magnetic Chucks for Lathes

Magnetic Chucks for workholding for Lathes

MAGNETIC CHUCKS FOR TURNING OPERATIONS

DESCRIPTION

In manufacturing processes involving wheel turning, bearings, rings, and flanges, workpiece deformation during clamping poses a common challenge.

Electro Permanent Magnetic (EPM) Lathe chucks offer a solution by clamping the workpiece from its base surface.

This setup allows uninterrupted tool paths and enables complete machining in a single setup.

By using pole extensions, the workpiece can be raised from the magnet surface, facilitating machining of both inner and outer diameters.

The magnetic system’s uniform clamping minimizes vibrations, resulting in significant benefits such as improved machining tolerances, extended tool life, efficient chip removal, and enhanced machine productivity.

InquiryFEATURES

HIGH EFFICIENCY

- Quick and efficient workpiece clamping

- Machining of outer and inner diameter in 1 setup.

- Tension free claming without deformation

95% ENERGY SAVINGS

- During the MAG and DEMAG phases, electro-permanent magnets require electricity for a only 3 seconds.

- This efficient power usage minimizes energy consumption and contributes to cost savings.

SAFETY

- Even in the event of a power outage, the workpiece remains securely held in place, eliminating the risk of it falling down.

- This feature ensures the safety of operators and prevents potential accidents or injuries.

MAINTENANCE FREE

- Electro-permanent magnet plates use electrical current only for magnetizing or demagnetizing (3 sec), preventing coil overheating and increasing lifespan.

- With no moving parts, they require no maintenance.